148

Borneo Bulletin Yearbook 2021

Shell 3D Printing Centre of Excellence located in

Amsterdam, the Netherlands.

A sample of the pump impeller was sent to

Amsterdam where reverse engineering – a

process that involves deconstruction of the

pump impeller to extract design information via

external and internal scanning – was used to

create a virtual replica of the pump impeller prior

to producing the actual 3D finished product. After

the once-off preparation for the printing, the real

printing takes nine days with a few additional

days for finishing and testing.

3D printing of spare parts results in a much

better finish in the quality and smoothness

especially in the intricate areas, leading to a

better performance. The material used was 316L

grade stainless steel, which not only makes the

pump impeller more reliable, it also increases its

longevity. With the completion of the engineering

work, the next 3D print of this impeller will only

need a push of a button.

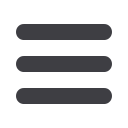

Similar to the company’s pioneering roots in

the LNG space, Brunei LNG is pioneering in the

digitalisation space, where engineers are doing

proactive technical monitoring of the plant and

advancing process optimisation through data

analysis. Brunei LNG has already delivered

additional millions to the company’s bottom line

by designing a plant that is constantly looking

for more gas from its upstream suppliers. This

automated feed system is working 24 hours

a day, seven days a week to ensure that all

available gas to the plant is consumed.

In the near future, Brunei LNG will be investing

significantly into making a digital twin of

its facility, giving engineers and operations

staff a digital version of the plant to interact

with. This will help in areas of operations,

maintenance, and even safety from incident

response planning to how a crane should

move within the plant for maintenance work.

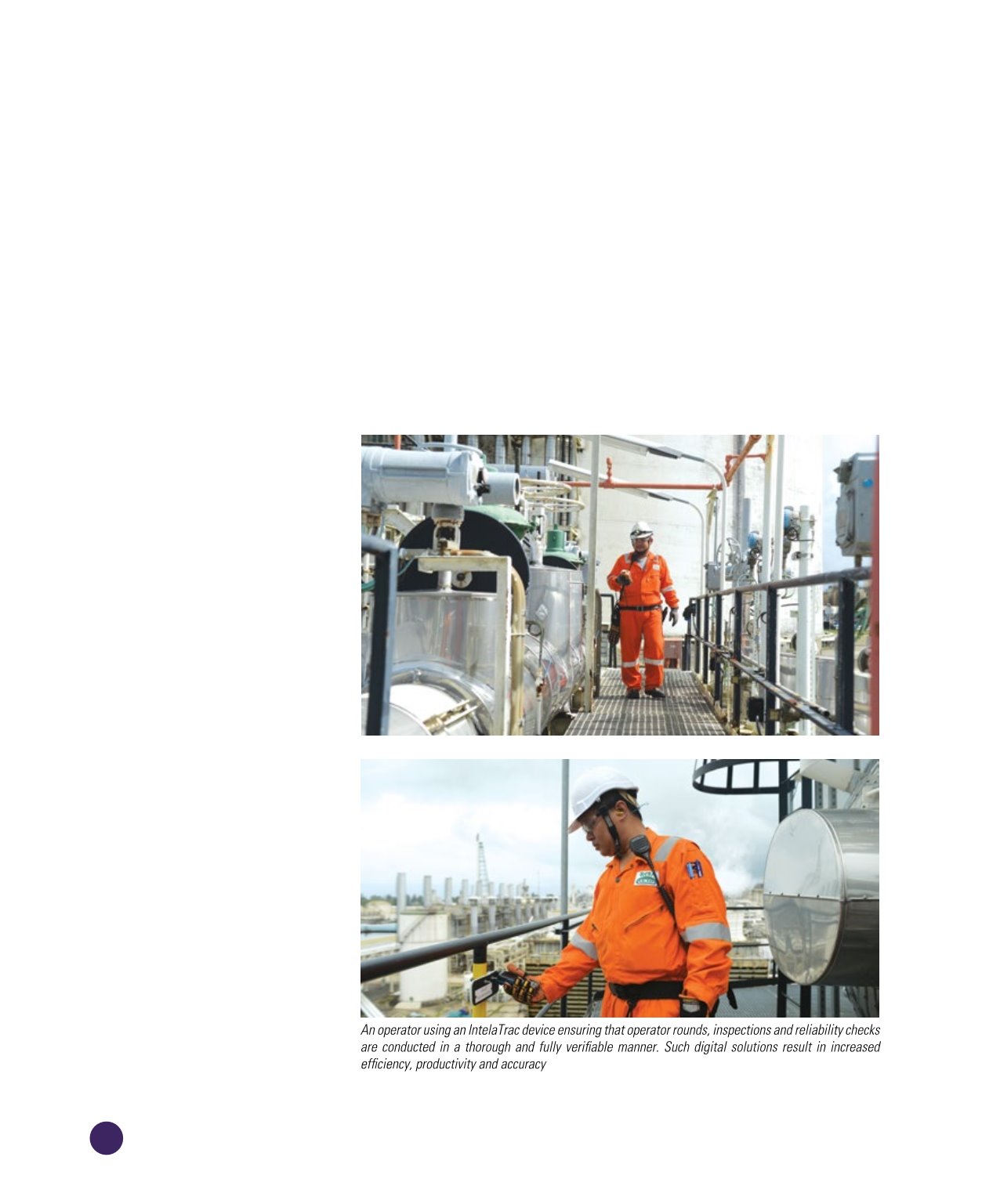

Additionally, around the corner is the digital-

enabled operator, where operations staff

will have the ability to troubleshoot a plant

problem with an office-based engineering

colleague, via streaming video of the problem

in question. The possibilities are vast and

endless, but Brunei LNG is generally targeting

the areas of visualisation, data analytics

(optimise maintenance, plant operation or

materials supply chain), digital twin (including

engineering data) and digitalised operations

(operator with mixed reality aids).

Digitalisation of course goes further than Brunei

LNG, and the company works closely together

with BSP and their digitalisation journey, sharing

ideas and solutions to challenges so that they

get the most out of the value chain. Together

with new gas coming in 2026, digitalisation is

certainly one of the biggest changes coming to

Brunei LNG in its 50-year history and it is a space

that will be heavily invested in.